Do Your Props Have the Right Cup, Rake, Slip, Pitch and Hub?

In: Boating

2 Jun 2011 The more we research some subjects the more we discover that some of the assumptions we have operated on for years are not correct. There is probably no field in the boating world that is more a of a black art, or where there is more mis-information than in re-propping. But getting the right prop is not really a matter of Voodoo. It’s more of a matter of finding out there is a prop problem (or a remedy) in the first place, then a matter of finding an expert you can trust who can recommend what you need. We hit the important basics and examine some alternatives in this short report on prop basics

The more we research some subjects the more we discover that some of the assumptions we have operated on for years are not correct. There is probably no field in the boating world that is more a of a black art, or where there is more mis-information than in re-propping. But getting the right prop is not really a matter of Voodoo. It’s more of a matter of finding out there is a prop problem (or a remedy) in the first place, then a matter of finding an expert you can trust who can recommend what you need. We hit the important basics and examine some alternatives in this short report on prop basics

You might not be able to do anything about your boat or engine, but you certainly can do something about your props. Are you really sure you’ve got the right wheels?

How Props Work?

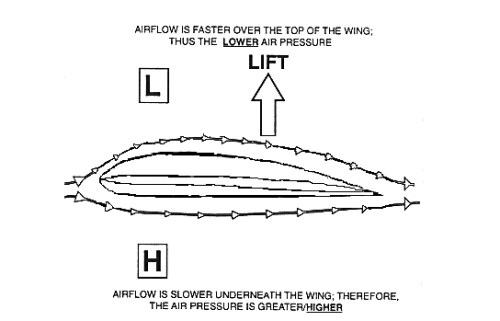

A propeller is not a screw, but it took decades before early prop makers realized that. Marine propellers work for a couple of reasons. A propeller is like an airfoil, or a wing generating lift. Remember the drawings you saw in grade school as to why airplane wings created lift and allowed a heavy plane to fly? That’s part of it.

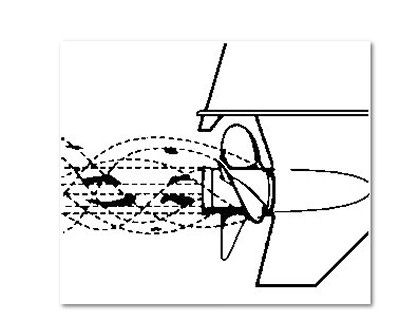

As the prop turns it pushes water down and back of its blades creating a positive pressure surface on the underside of the prop blade, and a negative pressure surface on the top/forward side of the blade.

A boat’s prop actually does not work like a screw There is far more sophisticated technology at work here.

A boat’s prop actually does not work like a screw There is far more sophisticated technology at work here.

The moving prop pushes water down and back creating a momentary “hole” in the water that is immediately filled by water rushing in to fill the “hole” which creates a low pressure area that provides “lift” and pulls the blade forward. As lift overcomes drag momentum is created in the water. This momentum produces thrust and moves the boat forward.

Get into the details of props and you will find quite a bit of complexity. That’s why it is difficult to buy the right prop off the shelf.

The Basic Parts of A Prop

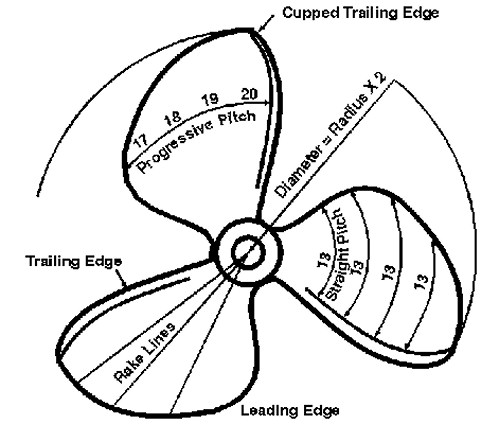

1. The Blade Tip — The extreme edge of the blade.

2. The Leading Edge– That part of the blade that cuts the water.

3. The Trailing Edge — That part of the blade from where the water leaves.

4. The Cup of the Blade — This is the curve in the trailing edge of the prop blade that extends from the hub to the tip. It adds pitch to the blade.

5. The Blade Face — That part of the blade that faces aft and is the positive pressure surface.

6. The Blade Back — The part of the blade facing forward that is the negative pressure surface of the prop.

7. The Propeller Hub — This is the metal base to which the blades are attached. On stern drive and outboard boats there will be an inner and outer hub. The inner and outer hubs are connected by thin ribs of metal or rubber with splines connecting the hub to the drive shaft. Both the metal ribs and the rubber are designed to protect the gears in the lower unit in case of grounding under power.

Prop Materials

Most props for outboard and stern drive boats are made of aluminum or stainless steel. Props for larger inboard boats are usually bronze or another malleable alloy. Aluminum props are inexpensive but are also relatively soft and flexible. Aluminum props are good for general purpose use and in applications where peak performance is not at a premium, so long as the owner understands that they are easily damaged.

While boaters wanting top speeds usually select stainless steel over aluminum, industry experts tell us that the material of the prop accounts for only about 10% of the prop’s performance- the other 90% comes from the prop’s geometry.

Stainless steel props are expensive because stainless steel is expensive to refine, and the molding process is also much more difficult and expensive than with aluminum. Stainless steel props are very hard and inflexible, and are far more durable when hitting small rocks, sand or objects in the water. The downside of having a S.S. prop with minimal give is that if you hit a rock with the blades, instead of the prop breaking, the shaft or gears in your lower unit or drive train may be ruined instead.

How Many Blades?

Most stern drive and outboard props are three or four blade, although some high performance boats may have five-blade or six-blade props. In inboard boats, props may have six, seven or even eight blades. In these cases the chord of the blades (the distance from the leading edge to trailing edge) will be more narrow than in the prop that has just four blades, in most cases.

Three-bladed props are generally used on stern drives and outboard boats where highest top speed is the objective, and four-bladed props are usually employed for faster hole shots and reduced vibration. Four-blade props generally have less steering torque. Five and six-bladed props are used in racing applications and in high-performance recreational boats.

Propeller Diameter

Diameter is the distance from the center of the hub to the tip of one of the blades times two. Generally the manufacturer of the lower unit or the outboard engine, or in the case of an inboard-powered boat, the builder, determines the diameter of the prop. There is usually little latitude when replacing a prop and it is wise to stay within a 1/2″ diameter of the original size prop, as a rule of thumb.

Diameter is the first number listed in a prop description. So, a prop described as 15 x 18 x 4, is a prop with a 15″ diameter, an 18″ pitch, and has four blades.

Propeller Pitch

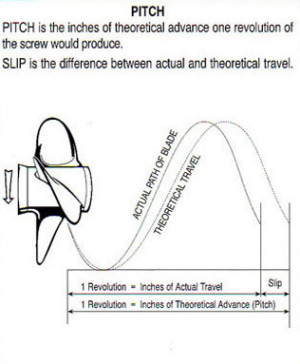

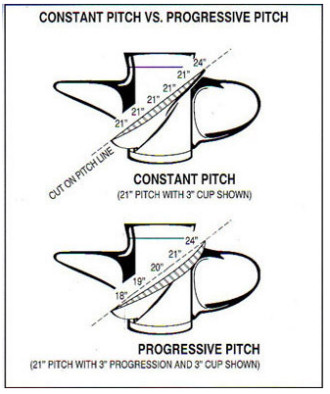

Pitch is NOT measured the same way as is diameter. It is NOT the distance from the leading edge of the blade where it meets the hub to any part of the trailing edge. Rather, pitch is defined as the theoretical forward movement of a propeller during one revolution assuming there is no “slippage” between the propeller blade and the water.

For example, an 18 pitch propeller will theoretically move 18 inches forward with every revolution as it cuts through the water. In fact, it will never achieve its theoretical distance of advance because of what is know as “slippage.”

Propeller slip occurs with every propeller, but the amount of slip varies depending on propeller design. Well-configured props will have as little as 10% to 20% slippage. How much slippage is the optimum amount for your application? It’s a question to ask a prop professional.

Choosing Prop Pitch for Your Application

Each engine manufacturer has preordained the WOT rpm of your engine and usually the pitch of the prop fitted to that engine will allow it to reach that rpm setting. If the engine cannot reach the intended WOT rpm, and if the engine is performing properly, it probably means that the prop has too great a pitch. A prop expert can suggest what pitch prop you should have based on the performance of your boat in relation to its factory-rated WOT rpm.

Changing the pitch of your prop will change the boat’s performance. Think of it in terms of a manual-shift car: the lower the gear the easier it is to turn high rpms. Likewise with a prop, the lower the pitch the easier it is to turn high rpms. In a car or truck if you are trying to go up a hill with a heavy load, the transmission must be downshifted into a lower gear making it easier for the engine to turn the rpms it needs to move the weight. The same is true in boats.

If you want a fast hole shot for water skiing or another purpose such as a bass tournament start, then you may want to lower the pitch of your prop. Also, if you plan on running your boat heavy because of the number of passengers or equipment aboard, you should consider lowering the pitch of your prop.

Conversely if you discover that you have purchased an under-powered boat, buying a prop with a lower pitch could be the least costly solution to your problem.

Cup size is important. It affects speed, fuel consumption and WOT speed.

How Much Cup?

The amount of cup a prop’s blades have, and where that cup is deepest on the blade, could have an effect on performance in terms of ventilation, slippage, hole shot speeds, fuel consumption WOT speed, boat trim and even propeller depth. Determining the geometry of your prop’s cup is best left to the experts. Tell them the performance you want and they will dial-in the right cup geometry.

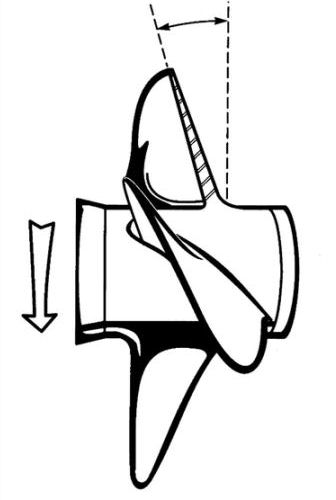

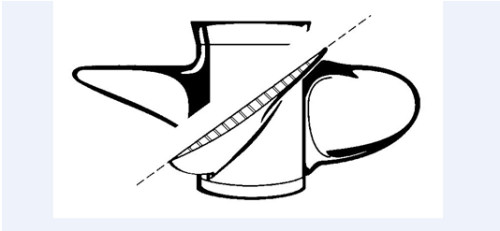

How Much Blade Rake?

Rake is an aspect of prop design that is not much discussed but it can be very important to your boat’s performance, or can correct some of its bad habits. Rake is the degree that the blades slant forward or backwards in relation to the hub. For example, aft rake helps to trim the bow of the boat upwards, which often results in less wetted surface area and therefore higher top end speed. Forward rake helps hold the bow of the boat down. Once again, this is a matter for prop experts to figure out once you have given them the facts of your application.

Recommendation

We are in hopes that this little exploration into the world of props has suggested some possibilities for enhancing the performance of your boat. Obviously, there is much more to getting the right prop for your application than going down to the local West Marine and buying one off the shelf. Our recommendation is to find a marine propeller expert who knows his stuff, has access to the latest technology, and gives good customer service.

Welcome to BeaverLakeBoaters!

This site is devoted to all things Beaver Lake Arkansas

Categories

Comments are closed.